3D PRINTING

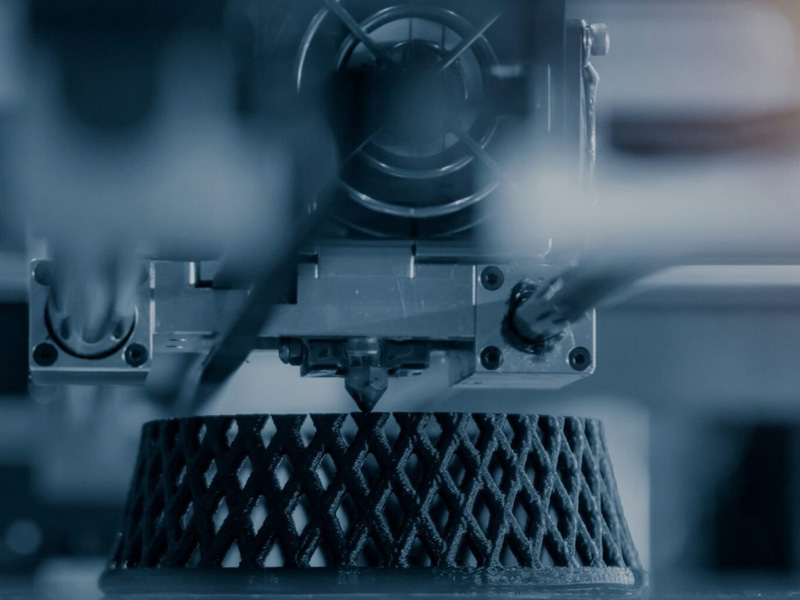

3D printing, also known as additive manufacturing, is widely used in engineering for various applications due to its versatility, precision, and ability to create complex geometries. Here are some common uses of 3D printing in engineering:

1. Prototyping

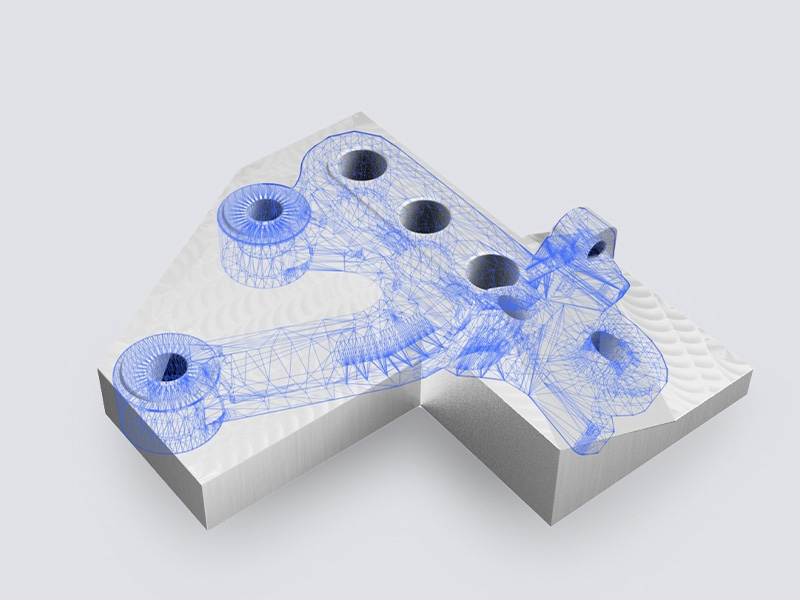

Rapid Prototyping: Engineers use 3D printing to quickly produce prototypes of parts or assemblies for testing, design validation, and optimization. This reduces the time and cost associated with traditional prototyping methods, allowing for iterative design cycles.

Functional Prototypes: 3D printing enables the production of functional prototypes that can undergo real-world testing. This is especially useful in various fields of engineering, where performance testing is critical.

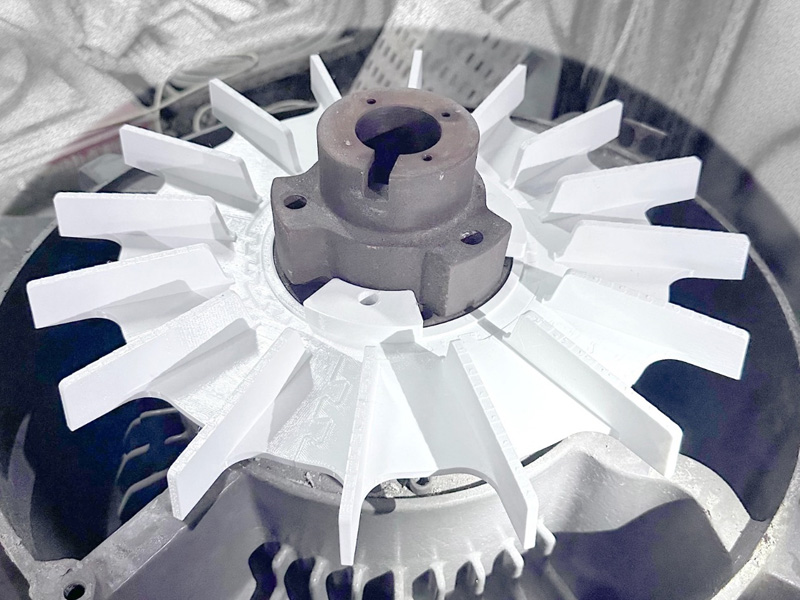

2. Manufacturing Custom Parts

Low-Volume Production: In engineering projects requiring custom, low-volume parts , 3D printing is ideal. It allows for on-demand production without the need for expensive molds or tooling.

Spare Parts: Industries use 3D printing to manufacture spare parts, particularly for older equipment where traditional production methods may no longer be feasible.

3. Complex Geometries

Topology Optimization: 3D printing enables the creation of complex, lightweight structures that traditional subtractive manufacturing methods cannot achieve. This is particularly valuable in aerospace engineering, where weight reduction is key.

4. Sustainability and Efficiency

Material Efficiency: 3D printing is an additive process, meaning material is only added where needed, minimizing waste. This makes it more sustainable compared to traditional subtractive methods like CNC machining.

Reduced Carbon Footprint: Engineers use 3D printing to manufacture parts closer to where they are needed, reducing transportation and supply chain inefficiencies.

3D printing is revolutionizing engineering workflows by providing more flexibility in design, reducing production costs, speeding up development cycles, and enabling the creation of parts that were previously impossible to manufacture using traditional methods